This is Part 3 of our journey through the typical brewery: what we see, what should be there, and what the implications are on profit, growth, and legacy.

You can circle back to Part 1 (Finance) here or Part 2 (Taproom) here.

Make the leap.

Dive in with both feet.

Lean in and plow forward.

These are the sentiments of the independent culture that makes this industry great.

These are also the things that can get us into trouble.

Especially when breweries set their sights on distribution.

There’s absolutely something to be said for trial by fire.

But there’s equally something to be said for not casting off into the ocean on a raft built for a calm river, only to be pummeled and destroyed by the massive swells and ocean currents.

Moving into distribution or expanding the distribution footprint are challenges we deal with often.

Whether it’s a calculated plan for growth or a nervous tension around extra inventory, the right steps are never clear.

Couple that with the planning it takes to pull in the resources, align cash flow, and scale up the brew frequency…

And the fact that distribution looks entirely different than it did a year ago…

Sheeesh.

We place ourselves in this pressure cooker for the promise of new markets, bigger tanks, brand recognition, and a pathway to growth and eventual sale.

These are all good things.

But moving out of the “safe zone” of the taproom into the wild world of distribution is no simple task.

There are big waves, bigger boats, and jellyfish.

The massive ocean currents will disorient and pull you away from your mission.

The bigger boats may crash into you, causing operational slowdowns.

And the jellyfish… well these guys are hard to see, and sting like hell when you encounter them.

In contrast to everything good and powerful and profitable we covered last week about the taproom and direct to consumer…

Distribution is a different game entirely, and the typical brewery is not prepared for it.

They enter “into the unknown” on that same blind faith that got them started in the first place.

And often end up in a frustrating middle-ground.

Just enough progress to keep the dream alive, but not enough profit to keep the engine turning over.

As a result, cash flow is squeezed…

And puts undue pressure on the leadership to make decisions that they don’t want to make, but have to to keep the ship afloat.

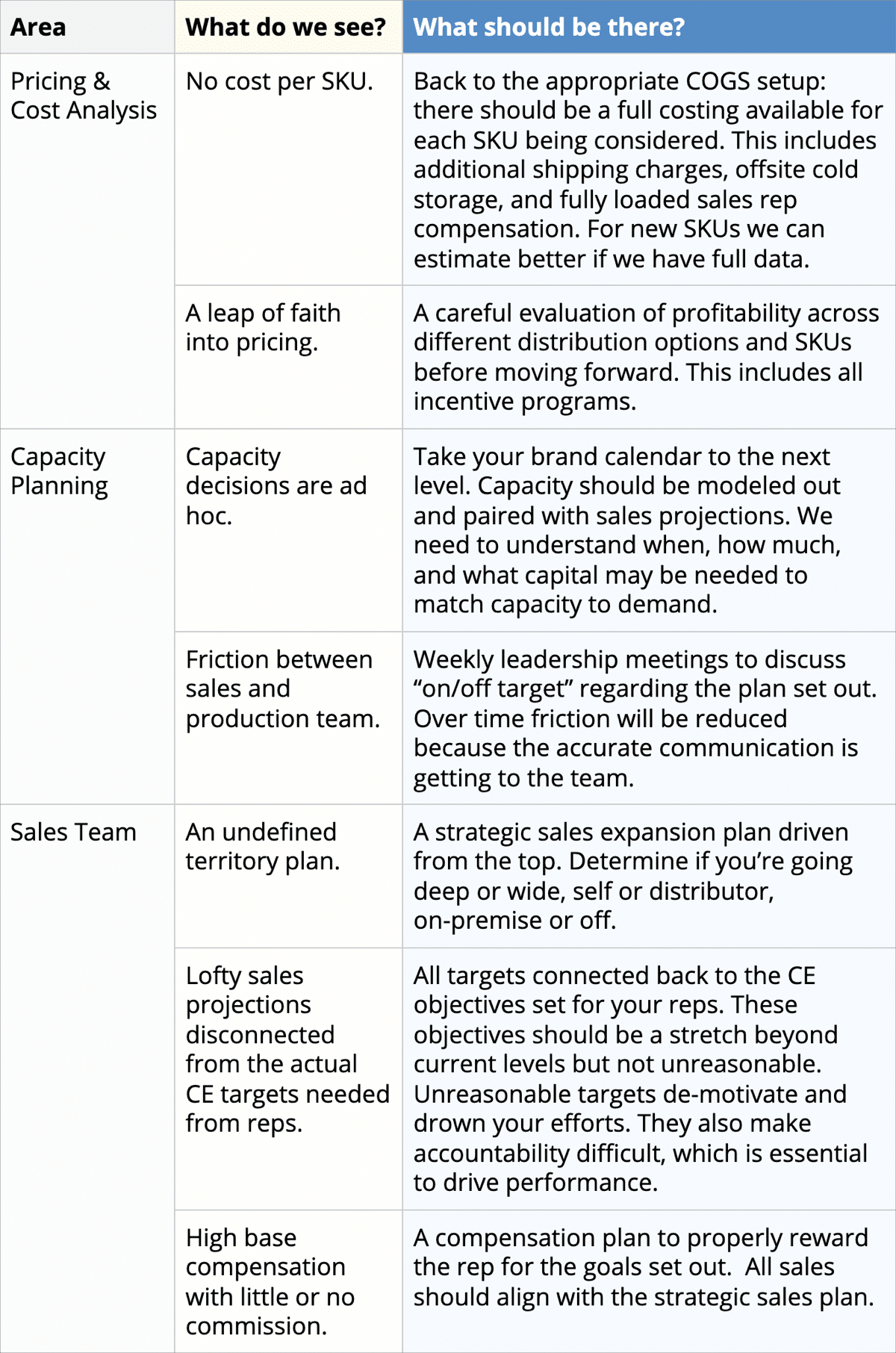

Below we cover what we see in distribution and operations for a typical brewery.

More specifically, what we see in:

- Pricing and cost strategy. What is our margin per SKU before signing on the dotted line?

- Production and capacity planning. How do we keep up with demand without going overboard?

- The sales team and their strategy, goals, training, and compensation.

The typical brewery isn’t clear enough on what it takes to achieve that success at scale…

Which is a careful, considered, and planned effort.

First up: pricing and cost strategy.

Because it’s the first obstacle the typical brewery runs up against right out of the gate.

Let’s dig in.

Dollar Signs In Distro: The Typical Brewery’s Pricing and Cost Strategy

On a trip to the beach recently, my youngest decided to open a store that cleans Crocs.

Simple concept for a 4 year old…

Clean off sandy Crocs in a beach bucket and BOOM, business is born.

When I asked him how much he charges for cleaning a pair, he said $100.

Now that’s a kid that’s got his eye on his margins!

This got me thinking…

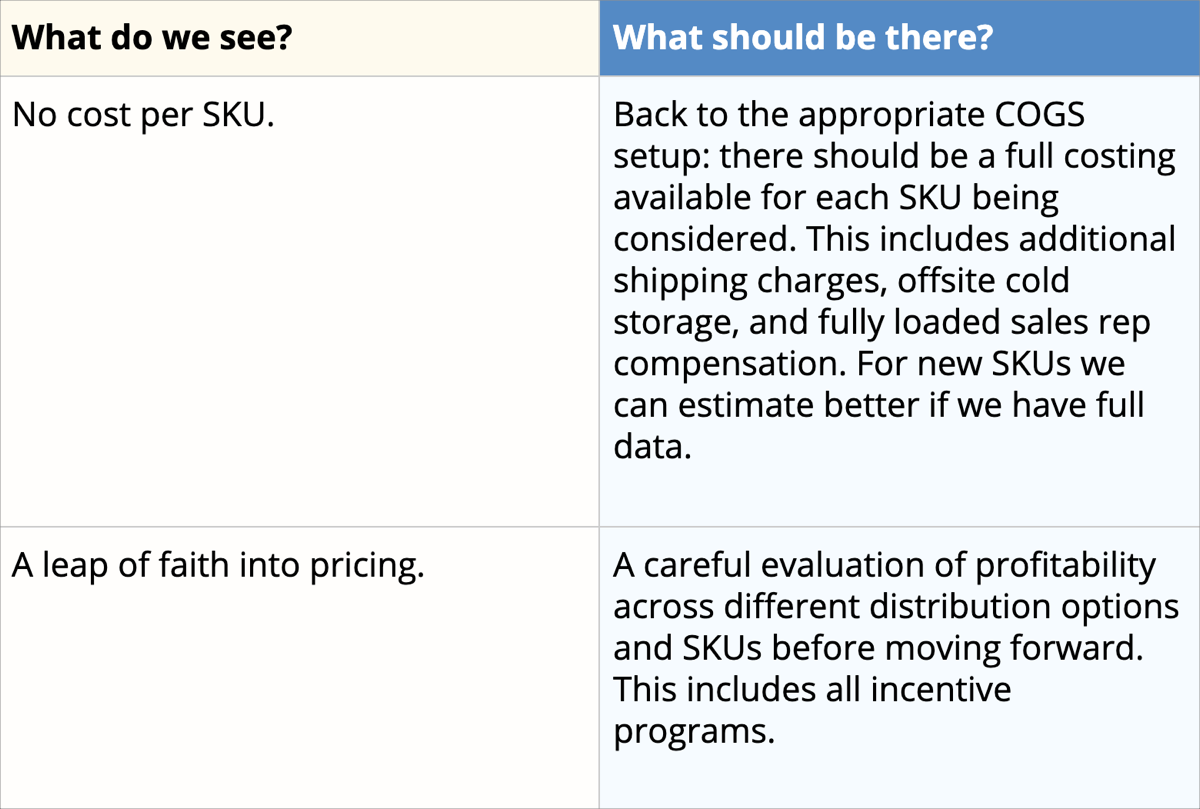

What do we see?

When the typical brewery considers moving into distribution, they see the dollar signs. They also figure this will be a great way to move lots of volume to their home market.

They may have encountered a roadblock to increase sales in the taproom so the immediate solution is to move into distribution. Others opened with the dream of having their product in accounts and on shelves.

The fantasy of their logo and art in people’s hands all over the U.S. is real.

Most understand this will come at a cost… lower margins to be more specific.

Everyone knows you take a hit when you go from retail to distro.

How much of a hit?

About 75%.

Ooof.

And so because most breweries don’t know the true margin on each SKU of beer that goes out into distribution, they anchor on a price with the distributor and hope that is enough to cover the cost of production, G&A, and a bit of profit.

For breweries that self distribute, it’s the same situation, only this time they are relying on what the other breweries are charging to remain competitive.

The attractive carrot of more revenue lures owners into a false sense of security that once the revenue is pouring in, the numbers will work themselves out.

They won’t.

Without a proper framework, it’s a shot in the dark… a guess that if volume increases the cost will be absorbed.

What should be there?

Instead, a full breakdown of cost per SKU is what’s needed in order to appropriately make this decision.

Based on those costs across different packaging styles we can then make informed decisions about volume vs. price and evaluate the offers that come back from the distributor.

What are the implications?

Without this analysis and careful consideration ahead of time…

This is how the typical brewery gets locked into bad distribution deals and kicks off the cash flow roller coaster: big cash outlays, longer payment cycle, less margin to cover the gap, feel the squeeze, rinse and repeat.

At the end of this cycle, the typical brewery realizes that while they may be producing more and generating more revenue, somehow there’s even less left over than before they started.

And from a profitability standpoint, they tread water at best and wash away EBITDA at worst.

The typical brewery needs to break the cycle.

This is again where intelligent decisions drive success.

But even when they do, there’s another problem we see crop up.

The Capacity Over/Under

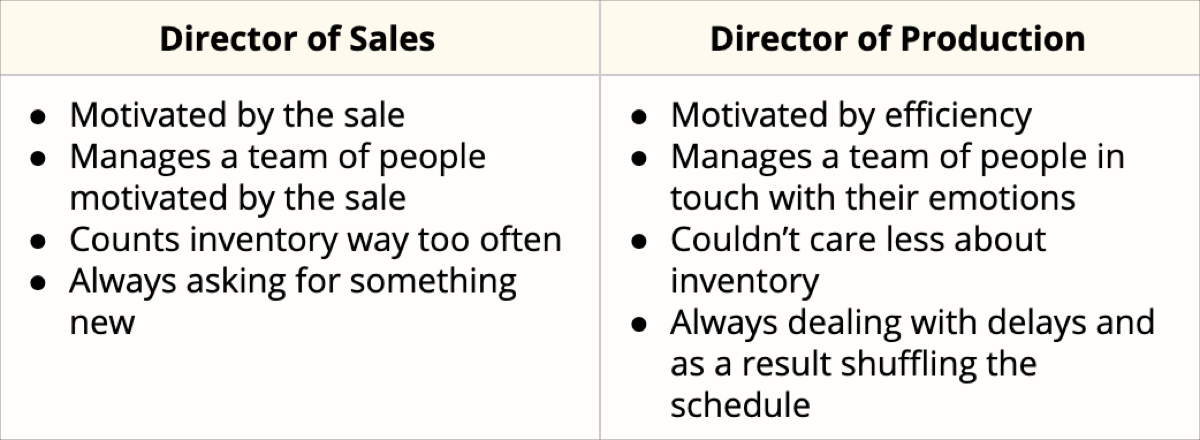

Sales and production don’t get along.

In most breweries, that is.

Because despite the need for those two critical functions to work hand-in-hand…

Your Director of Sales and Director of Production are constantly at each other’s last nerve with who’s request is more important.

Let’s take a look at the fight card.

So who wins?

Answer: everyone loses.

When entering or expanding distribution, the last thing a brewery can take on is increased in-fighting between the sales and production teams.

In a typical brewery, there are major resentments between the two groups.

The end result is bottleneck after bottleneck.

Bottlenecks which can be avoided with capacity planning.

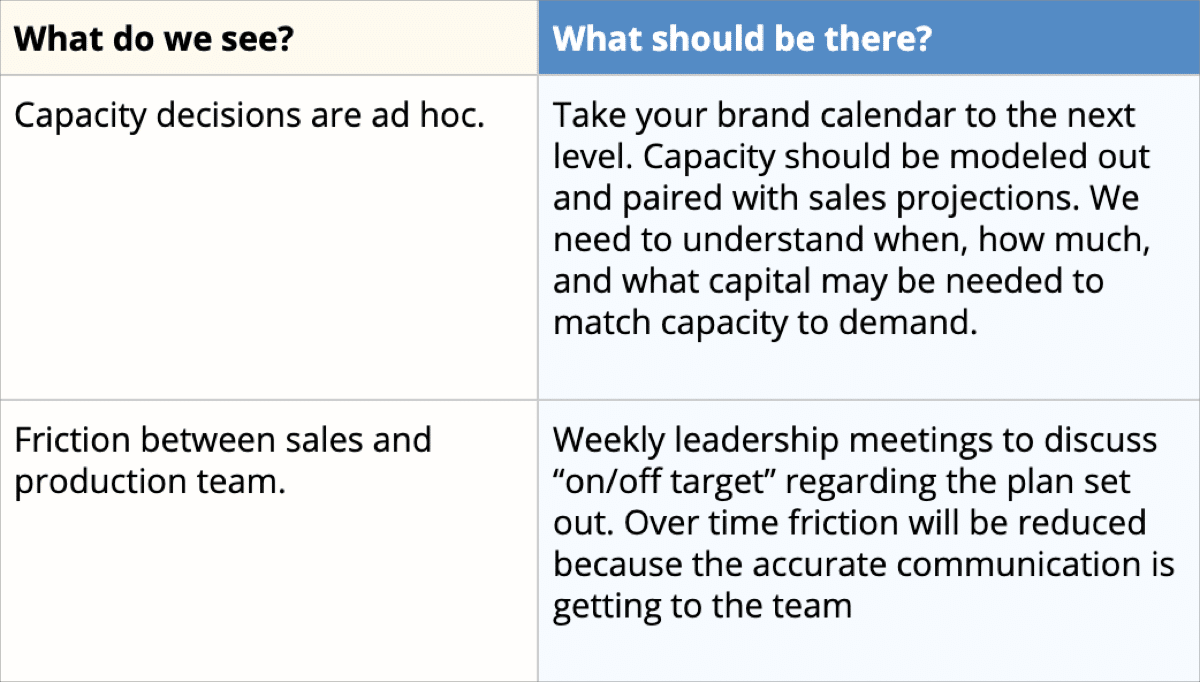

What do we see?

Specifically, capacity planning in the typical brewery is done as an afterthought.

Let me digress and preach about assets for a minute.

Any bean counter will tell you that when the assets sit idle they are not making money.

And so the typical brewery owner is thinking in these terms. Increase capacity, figure out how to maximize that capacity.

But that’s a bit backwards.

Yes we want to increase our utilization. The more the tanks are filled, producing delicious beer, the more the cost of that equipment is being amortized.

But in order to appropriately decide WHEN is the appropriate time to increase capacity is the key. And that should be driven by actual sales projections.

And that brings us full circle to why we need to smooth over this century old feud between the departments.

What should be there?

Instead, capacity should be inextricably tied to sales.

Every sales projection should include a parallel capacity projection so that we can incorporate the resource needs into the mix before pulling the trigger.

And when capacity is tuned to demand, we produce an efficient organization.

An optimized solution.

What are the implications?

It’s very easy, especially for the brewmasters among us, to get excited about producing more beer. A bigger brewhouse and more tanks is a flex. Proof that you’re doing something right.

But, although it may be in the best interest of your brewing ego, it’s not always in the best interest of the brewery.

In the lean manufacturing world this is called right sizing (and lot’s of discussion of this concept lately).

It means we’re optimized, but also flexible.

What would it look like if equipment wasn’t a barrier to growth?

What would it look like you weren’t burdened by unnecessary equipment?

The right type of capacity planning can ensure the following:

- Raw material and packaging inventory is ready and available when needed.

- Finished goods inventory is actually available to be sold.

- Assets (equipment and machinery) are being utilized to their full potential.

- Scheduling delays and expedited shipping charges are avoided.

- Zero friction between the directors of departments.

It removes yet another variable off of the table so you can focus on what really matters: brewing delicious beer and delivering it to customers.

Pretty nice right?

Next up in our series: sales.

This one is always a doozie.

Sales Team 2.0: We’re still not there yet

I love a good sales call.

Anyone who’s been on one with me has witnessed the sheer joy first hand.

The conversation and exchange of ideas.

The recognition of a need that we’re able to help fulfill.

It gets me excited, revved up, in my happy place.

And I want to unleash our team to get in there and do our thing.

But…

I also know that excitement and enthusiasm alone aren’t enough to get the job done.

It needs to be the right fit.

To align with both their team, objectives, and needs as well as ours.

And so there’s for more that goes into a successful sale than just “getting out there” and winning business.

It needs to be measured, strategic, intelligent…

This is true in the brewery as well.

And the typical approach we see is far from strategic.

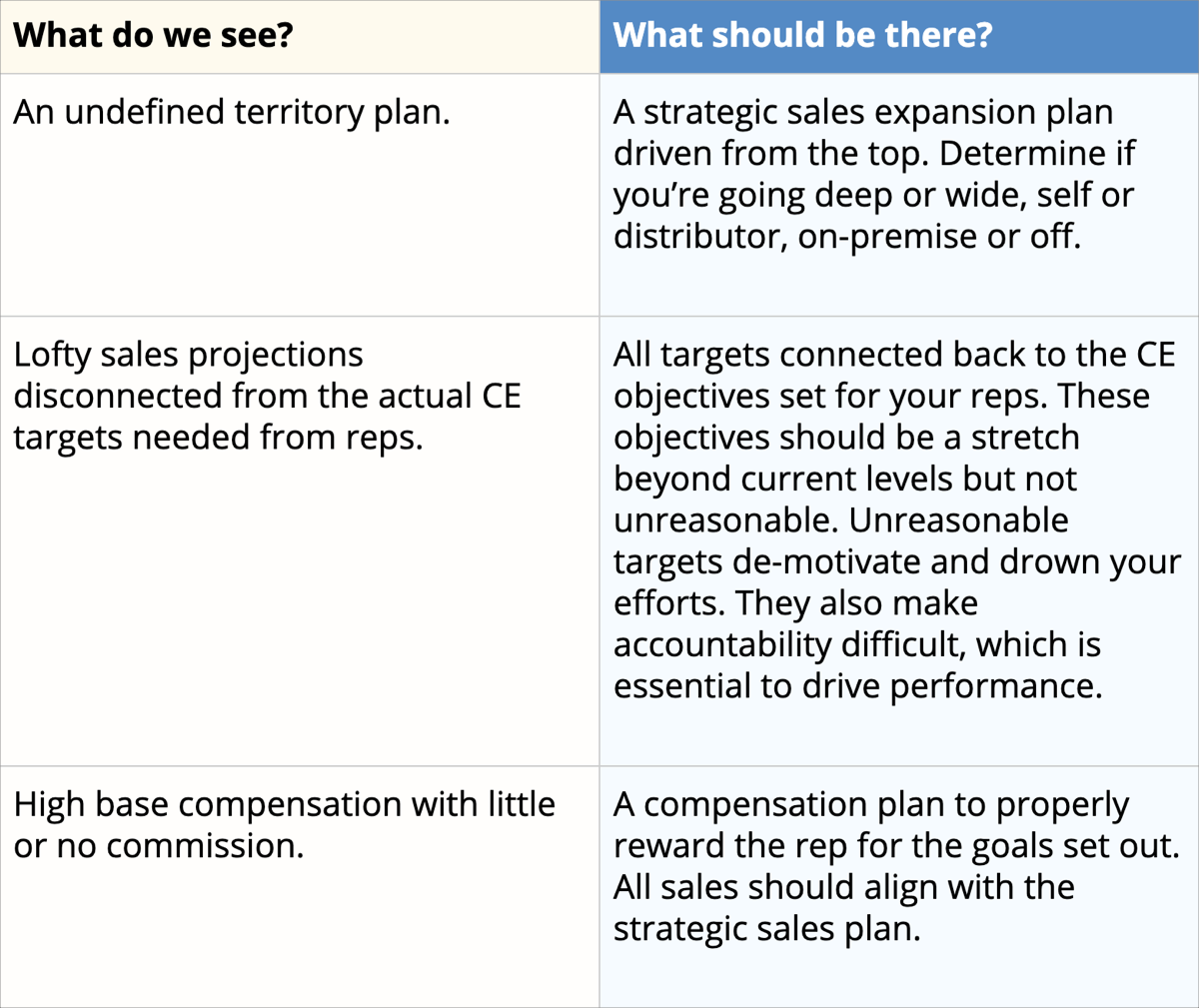

What do we see?

The typical brewery approaches distribution with a buckshot strategy. With complete focus on the sale, this thin and wide movement yields slow results.

Every tap or placement appears to be a “win”. A win for the brewery and a win for the sales rep.

Sales reps should be compensated on taps or placements, but in most cases they are not. The typical pushback I hear is:

“We don’t distribute enough for our rep to make a living wage”

“Do we pay commissions on what we sell to the distributor or the pull-through?”

“How do we set a competitive compensation plan for our sales team?”

The typical brewery does not have reliable projects and targets set that reps can go out and achieve.

It’s all over the map.

What should be there?

So that strategic approach to pricing, costing, and planning we just covered?

Yea… that came first for a reason.

Because if you understand the type and quantity of sales needed to support the brewery’s growth before your reps are cast out into the market…

It becomes exceedingly clear what your sales expansion plan should look like, as well as what your CE and account visit targets should be for each rep.

Speaking of CE targets, they need to be aggressive but reasonable, directly tied to compensation, and connected to a consistent system of accountability.

We’ve covered these best practices many times before.

They’re worth revisiting.

What are the implications?

A sales team is in many ways the lifeblood of the brewery’s future.

Unfortunately, the typical brewery treats sales like a “plug and play.” Sent off to blow in the wind…

And that couldn’t be further from the truth.

Instead, they’re the group of individuals that if properly motivated, aligned with the goals of the organization, and incentivized will grow the top line as fast as you can fulfill it.

They’re also the group of individuals that if demotivated, misaligned, and left to their own devices will bleed away resources, continually disappoint, and create a stressful burden on you and your team.

I have witnessed what happens when a sales team comes together to execute a strategic sales plan with the right compensation in place.

It’s a sight to behold.

When the pressure valve is replaced with clarity, structure, and action items, motivation thrives.

And that shift does magical things for the brewery.

Let’s add some magic to the mix.

Typical Distribution and Operation: Wrapping Up

Distribution and operations in the brewery are like a complex dance.

And when coordinated well it can be beautiful.

But if not coordinated well…

It all starts to look a little like your drunk uncle trying to keep up with the Electric Slide at your sister’s wedding.

This is usually where we find the typical brewery.

Each piece of the puzzle is functioning and does well enough to get by, but they’re not tied to the overall strategy.

They’re not integrated.

And that means that when the brewery decides to distribute, to expand, to do more and make more… they’re doing so on a hobbled foundation.

Let’s recap what we covered.

The taproom has been such a profitable arm of the business that we can get away with some “slack in the joints” and still make money.

In distribution and high volume production it’s a different story and this deep understanding of costs, pricing, capacity, and sales capabilities is essential. It’s the next level of performance the typical brewery has not yet unlocked.

It also happens to be exactly what’s needed at this moment in time…

When taprooms have been shuttered and breweries have been forced to figure out how to get more packaged product out the door to stay afloat.

The Numbers Come Full Circle

Here’s where what we talked about in Part 1 comes full circle.

That an understanding of the numbers is the starting point we need in order to make intelligent decisions and profitable distribution a reality.

Without it, the brewery truly is flying blind.

The Rogue Spreadsheet leads to the back of the napkin projection…

Leads to the ill-conceived equipment purchase, leads to the unfavorable distribution contract…

Leads to the rushed rep hire, the under-performance versus the lofty ungrounded sales projections…

Leads to the cash flow roller coaster, and the squandering of potential.

It’s more important now than ever that we get this dialed in.

Because under unfavorable conditions, the decisions we make have to be better, more intelligent, more strategic.

This is what we live for here at SBS.

We exist to enable and empower breweries to make those decisions.

The ones that unlock growth and profit, even in the face of uncertainty.

The ones that change the status quo.

It’s the path forward.

The best one in our view.

Good decisions start with the numbers, incorporate the vision of the founders, and come to fruition through leadership and disciplined execution.

Speaking of vision and leadership…

That’s next week.

And with that we wrap this series.

Keep fightin’ the good fight.